INFO: Aufgrund von IT-Wartungsarbeiten verkürzte Bestellannahmezeit am Freitag, den 25.08.2023 +++ Bestellannahmeschluss um 12:00 Uhr +++ Ab Montag, den 28.08.2023 sind wir wieder wie gewohnt für Sie erreichbar.

Whether wet or dry installation, dimpled sheet or fixed rail: with our modular PRINETO panel heating system, everything is possible - even the cooling of buildings. Our self-crosslinking PRINETO ÖKO-FLEX panel heating pipes are particularly practical, green-linked, made of polyethylene PE-HDS. They are particularly flexible and cross-link when first used due to the warm heating water. This saves up to 35 % electricity during production. Afterwards, they correspond to a PE-X pipe in their strength properties - for optimum comfort, long durability and an excellent energy balance.

PRINETO room temperature controllers combine user-friendly operation with sophisticated technology for maximum user benefit.

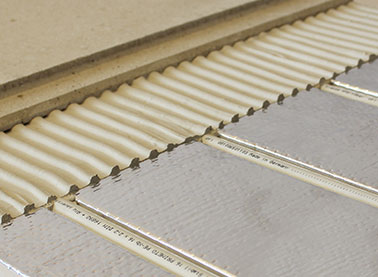

The PRINETO tacker system is our classic with particularly little waste. The unique, self-adhesive stapling foil or the top layer of the system roll/plate serve as a holding foil for the stapling needles.

Unroll the tacker foil over the foil foot of the edge insulation strip on the insulation and glue the joints overlapping.

When using system roll and system board, bond the foil overlap with adhesive tape so that it is screed-tight.

Lay the panel heating pipe starting at the upper beam of the heating circuit manifold according to the laying grid and the pipe spacing and fix it to the insulation with the PRINETO stapler using PRINETO staples.

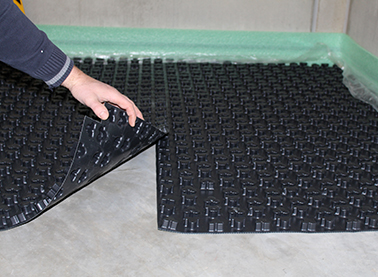

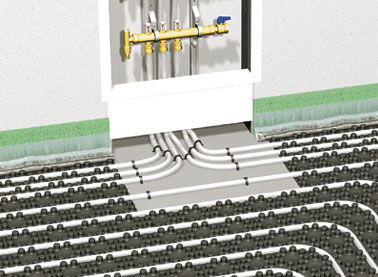

The PRINETO knobbed panel is the first choice for quick and particularly clean installation. With it, surface heating systems can be installed without tools and two different insulation thicknesses provide the appropriate insulation that conforms to standards. Our tip when a particularly low floor construction height is important: the PRINETO studded panel without insulation.

Lay out studded boards in all rooms so that the foil foot of the edge insulation strip lies on the studs.

If you are starting to lay a new board, first cut off the excess bubble foil on the sides of the wall.

Join the studded panels to be joined with overlap over the previous studded panel.

In front of the heating circuit manifold or in all areas of expansion joints, lay PRINETO levelling boards (without profile) in place of the studded boards.

In doorways or between heating circuits, stick the self-adhesive PRINETO expansion joint profile to the surface of the levelling board.

Then flush and vent each heating circuit individually with water and carry out a pressure test on connected heating circuits.

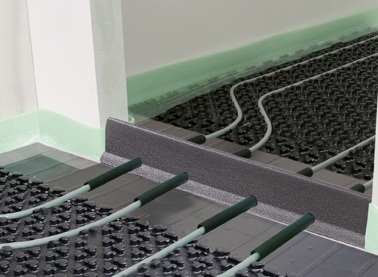

PRINETO fixed rails are our solution when it comes to large surfaces. They are particularly suitable for fixing surface heating pipes, e.g. in sports halls or on industrial and outdoor surfaces. The PRINETO fixed rail is ideally suited for fixing heating pipes to wall surfaces in wall heating installations.

Shorten the one-metre-long, self-adhesive PRINETO fix rails at the predetermined breaking points (10 cm each) without tools, depending on the installation direction and installation method, and stick them to the insulation surface.

Ensure a distance of max. 1 m.

Press the pipe with the foot into the fixed rail according to the selected installation type and the selected installation distance. Fasten pipe bends with short fixed rail pieces.

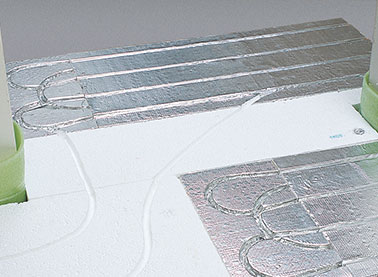

When wet systems are not suitable, the PRINETO drywall surface heating systems come into play. They are quick and easy to install. Thanks to their low weight and low installation heights, they are ideally suited for use in timber construction ceilings, e.g. in prefabricated construction and renovation. In addition, PRINETO dry construction panel heating systems impress with their high compressive strength and particularly low-cut installation.

Start of installation in a room corner with PRINETO reversible element.

Connection of PRINETO groove elements across the corner.

Doorway with PRINETO levelling element.

PRINETO hot cutting tool for preparing individual pipe guides.

Laying the PRINETO stabilising pipe.

Bonding of the dry screed elements with PRINETO special adhesive.

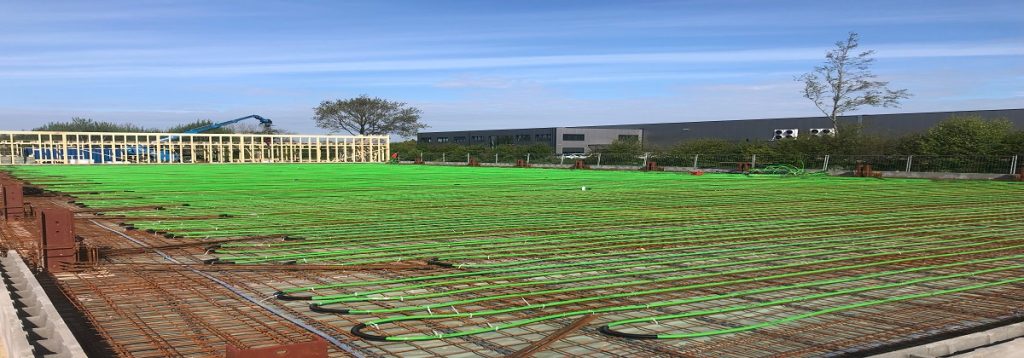

Our solution for industrial floor heating or thermal component activation is the cross-linked, highly flexible PRINETO surface heating pipes with dimensions of 20 x 2.0 mm and 25 x 2.3 mm. Special, large-volume 2-inch stainless steel manifolds with either regulating valves or flowmeters are used to distribute the heating or cooling circuits. Original PRINETO special tools and accessories enable fast and standard-compliant installation.

Distributor connection.

Laying the heating circuits, pipe fixing.

Cut-free installation possible due to couplings.

PRINETO thin-layer underfloor heating systems impress with a height of only 2.2 cm and are as quick as they are clean to install. Thanks to the sophisticated technology, the PRINETO thin-layer underfloor heating system impresses with its high thermal conductivity and heating performance even at extremely low temperatures.

Start laying the self-adhesive PRINETO bubble foil in the room “top left” opposite the door and continue to the right to the right wall of the room.

Press the pipes between the studs with the foot according to the installation type and spacing.

Use a suitable screed for thin-layer construction, e.g. Würth CERAfix 222.

Our pre-assembled PRINETO heating circuit distribution cabinets are now also available ready-wired, incl. Vario terminal strip and actuators in various sizes, equipment (with ball valve, heat meter connection group and optionally with water meter installation section, in each case horizontal or vertical) and variants (surface-mounted 80 mm or 110 mm deep or flush-mounted 126 mm deep, connection in each case right or left).

Galvanised sheet steel, frame, door and screed baffle finished in white RAL 9010, fully assembled incl. stainless steel heating circuit manifold with flowmeter, return with thermostatic valve inserts and manual regulating caps (connection thread M 30 x 1.5), flow with lockable, integrated flowmeters optionally with:

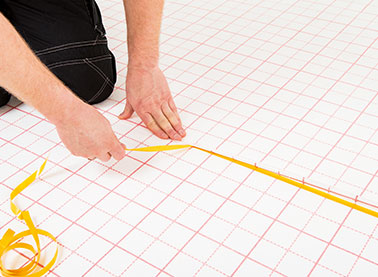

It couldn’t be easier or faster. The PRINETO hook-and-loop surface heating pipe is spirally wrapped with a hook-and-loop tape and can be laid on the specially laminated PRINETO hook-and-loop fleece in no time at all in a one-man operation.

An all-rounder on many substrates: On cement screed and flowing screed, the PRINETO Velcro system proves to be a real all-rounder. This is made possible by the water-permeable hook-and-loop fastener and the self-adhesive film overlap. Fleece is screed waterproof according to DIN 18560.

Unroll the Velcro system roll and fit it into the room.

Fix the edge insulation strip to the Velcro system roll using the adhesive strip (with adhesive tape at the head ends).

Connect the Velcro system rolls to the side of the film overlap with the adhesive strip.

Lay the Velcro surface heating pipe from outside the room using the door pipe guide (optional).

Attach the Velcro surface heating pipe to the insulation with slight pressure.

For the manifold connection or pipe connections, unwind the Velcro tape of the heating pipe approx. 5 cm wide and cut to length with a cutter knife.